In the world of automotive repair, precision is paramount. Whether it’s repairing minor dents or major collision damage, ensuring that a vehicle’s frame is perfectly aligned is crucial for safety, performance, ADAS (Advanced Driver Assist Systems) technology, and aesthetics.

This is where a frame machine comes into play.

In this blog post, we’ll delve into the world of frame machines and explore their significance in the automotive repair industry, with a special focus on the 10-ton pull capacity provided by Car-O-Liner.

What Is a Frame Machine?

A frame machine, also known as a frame rack or frame bench, is a piece of equipment used in auto body repair shops to straighten and align a vehicle’s frame or unibody structure. This technology is essential for restoring the structural integrity of a vehicle that has been involved in a collision or suffered frame damage due to various reasons.

Key Components of a Frame Machine

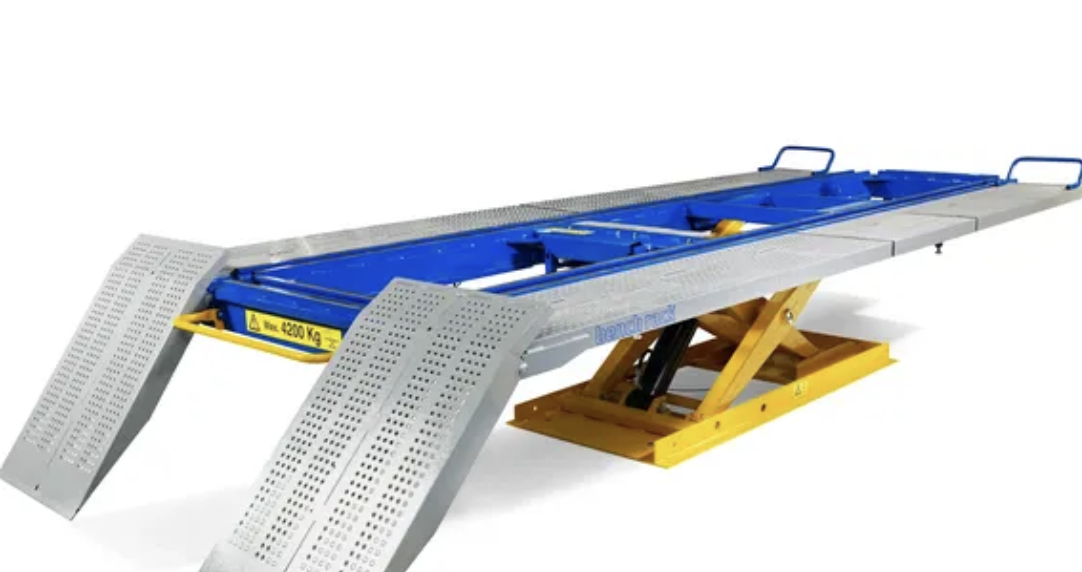

1. Platform: A frame machine typically consists of a sturdy platform where the damaged vehicle is secured. This platform is designed to accommodate various sizes and types of vehicles, ensuring flexibility in the repair process.

2. Clamping System: To hold the vehicle securely in place during repairs, frame machines are equipped with a clamping system. These clamps grip onto specific points on the vehicle’s frame or body, allowing technicians to work with precision.

3. Pulling: Being able to reverse the damage caused in a collision aids the technician in returning the vehicle back to factory specifications. These systems generate the necessary force to pull, push, or twist the vehicle’s frame components back into alignment. The force capacity of a frame machine can vary, and the 10-ton pulling capacity available in the Car-O-Liner Benchrack indicates its ability to exert a significant amount of force.

4. Measuring and Alignment Tools: Frame machines are often equipped with advanced measuring and alignment tools, such as lasers or digital cameras, to ensure that the vehicle’s frame is brought back to its original factory specifications accurately. As vehicle technologies change it is important to ensure the vehicle’s structure is properly straightened prior to any suspension alignment, or ADAS calibrations

5. Scissor Lift: The inclusion of a high scissor lift is a notable feature as it provides added flexibility in positioning the vehicle for repairs. This can be especially useful when dealing with damaged undercarriages or hard-to-reach areas of the vehicle. The combination of a high pull capacity and scissor lift not only ensures precision in frame alignment but also increases the efficiency and productivity of the repair process. Technicians can work more effectively, saving time and reducing labor costs.

In the world of auto body repair, a frame machine is an indispensable tool for restoring damaged vehicles to their pre-accident condition.

Whether it’s straightening a vehicle’s frame after a collision or ensuring that it meets safety and performance standards, frame machines play a vital role in the automotive repair industry. Their ability to restore structural integrity not only enhances safety but also ensures that vehicles look and perform as they should, giving peace of mind to both auto repair professionals and vehicle owners.